How to Identify Your Lift Station Problem

How to Identify Your Lift Station Problem

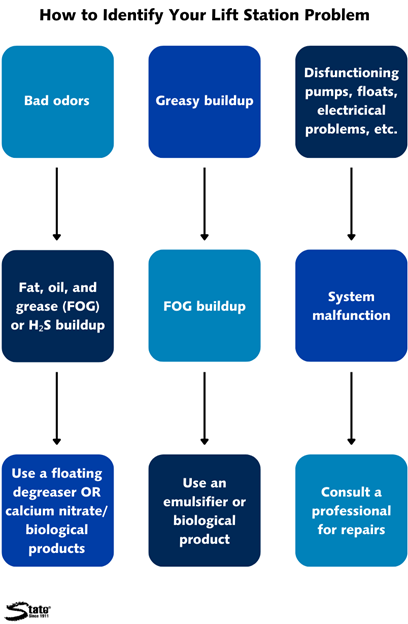

Sometimes, your lift station experiences issues. It might have a putrid odor, an unappetizing grease cap, strange equipment malfunctions, or something else. Whatever the case, you don’t want it to have issues—and you definitely don’t want your lift station to malfunction or experience downtime. So how do you identify the problem before it gets worse?

At State Chemical, we manufacture and distribute chemical solutions for various purposes, including lift station maintenance. It can be difficult to determine the right course of action when you don’t completely understand what’s wrong, and if you don’t specialize in lift stations, this may be hard to learn without outside help.

To help you identify what’s wrong with your lift station, we will explain the reasons behind odors, buildup, and equipment malfunctions in lift stations as well as solutions to these problems. After reading, you’ll know what your lift station’s problem is and how to approach it.

Why Does My Lift Station Smell?

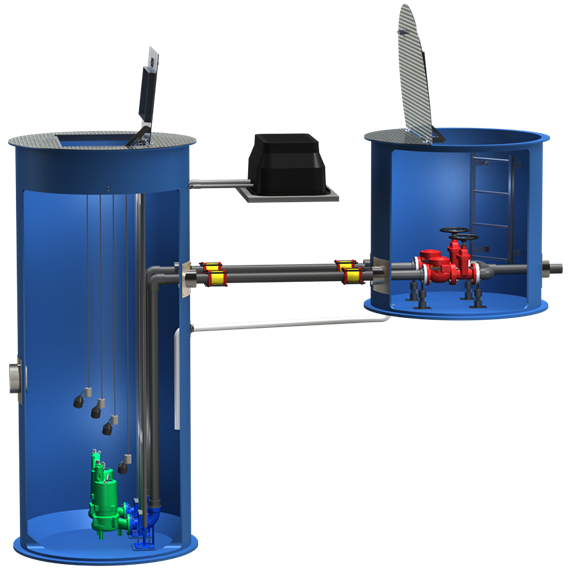

Lift stations are, in essence, a way of collecting waste. As a result, they tend to have odors—and some of these odors can be really, really bad.

It goes without saying that no one wants to frequent an area that smells. When lift station maintenance is required, this can be an unpleasant reality. Additionally, if your lift station odors are seeping into other parts of your facility or turning into a nuisance for nearby homes and businesses, it doesn’t exactly create a welcoming atmosphere.

So, if lift station odors are your main problem and they aren’t necessarily accompanied by severe fat, oil, and grease (FOG) buildup, your solution is to use a floating degreaser. Degreasers break up FOGs to prevent future buildup and cap off odors, making the area smell pleasant rather than putrid.

However, if your lift station has an odor of rotten eggs, you may be facing another problem. Hydrogen sulfide (H₂S) is known for having this odor, and it’s prone to develop in lift stations. If you notice this odor, it’s best to use either a calcium nitrate product or a biological product to reduce H₂S. Not only does H₂S smell bad, but it’s a safety concern that must be mitigated as much as possible.

Pay attention to the specifics of your odors and you’ll be able to find the best solution for your lift station.

Why is There Greasy Buildup in My Lift Station?

Your lift station might also deal with FOG buildup floating through the wet well or creating a grease cap at the top. This can be in tandem with odors or its own problem.

As we know, lift stations process a lot of waste—it’s their whole purpose. When this waste consistently filters through the lift station, it can leave behind residue in the form of FOGs. And when FOGs build up in your lift station, they can impair the functionality of pumps and floats, which can lead to mechanical failures.

This is why you need to get your lift station pumped from time to time: FOGs build up, and they need to be removed for the lift station to continue to function properly. Unfortunately, in the case of severe FOG buildup, these pump-outs may be required very frequently, creating an additional hassle.

To avoid these outcomes, the best treatment is to prevent FOG buildup in the first place.

By using emulsifiers and/or biological products, you can reduce the FOG buildup in your lift station.

Upon encountering them, emulsifying products quickly liquefy FOGs. Then, the FOGs easily pass through the drain line with the water rather than gumming up your lift station. This is a quick-acting solution, but emulsifiers can cause FOG reformation down the drain line and are heavily regulated in certain municipalities as a result. Check local laws before purchasing emulsifying products.

Meanwhile, biological products enlist bacteria to consume FOGs in your lift station. From there, the FOGs are digested, leaving behind only water and air, which helps them to pass easily through the lift station. Even if you stop using the biological product, the bacterial colony will continue to grow as long as it has livable conditions (a food source, temperatures of at least 40°F and no more than 120°F, and a pH of 6–9). While initially slow to yield results, this is a long-term solution to prevent FOG buildup and maintain your lift station.

Emulsifiers and biologicals effectively control FOG buildup, and either could solve your lift station problems.

Why is My Lift Station Malfunctioning?

System malfunctions are another trouble lift station issue. Maybe your pumps aren’t working. Perhaps your floats aren’t sensing the right water levels. Maybe you’re experiencing constant electrical problems.

If you’re in these situations, chemical maintenance is not the answer. Instead, you’ll want to contact a professional for direction about your specific situation. From there, you will be able to properly identify the issue and schedule any necessary repairs.

For general and preventative maintenance, chemicals can be a great solution. But at a certain point, a specialist will be of more use to you.

How to Choose the Right Treatment for Your Lift Station

Lift station problems can be a big deal, and you don’t want them to worsen and turn into an even bigger issue. Now that you know how to identify your lift station’s problem, read this article to learn about how to choose the right treatment for your lift station.