The Facilities Manager’s Guide to Fat, Oil, and Grease (FOG) in Drains

The Facilities Manager’s Guide to Fat, Oil, and Grease (FOG) in Drains

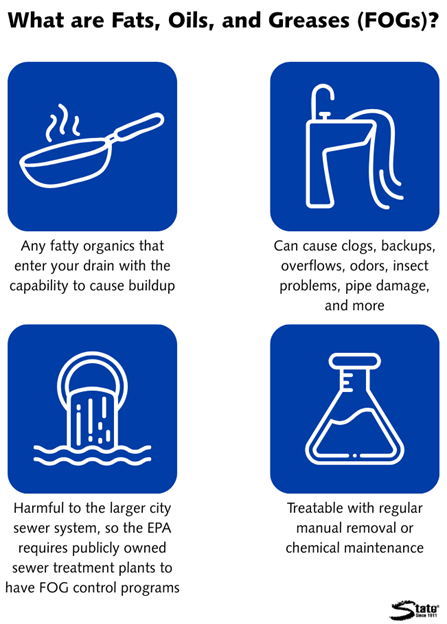

Pipe clogs, sink backups, grease trap overflows, lift station odors, and more: all disastrous outcomes of fats, oils, and greases (FOGs) in your drain lines. But what are FOGs, why do they cause problems, and what can you do to prevent them from negatively affecting your facility?

At State Chemical, we manufacture and distribute biological and chemical solutions for various applications, including FOG control in drains. We know it can be difficult to understand what to do about FOGs without first understanding why FOGs are a problem.

To help you realize how FOGs can negatively impact your drains, we will explain what FOGs are, the issues they cause, the regulations against them, and how to prevent them from building up. After reading, you’ll better understand FOGs and how to reduce them in your facility.

What are Fat, Oil, and Grease (FOG)?

FOGs can refer to virtually any organic, but in this situation, they more specifically refer to any fatty organic that enters your drain with the capability to cause buildup. This can mean the more obvious substances that may come to mind (e.g., bacon grease, canola oil, butter, etc.) as well as less obvious items (e.g., milk, salad dressing, peanut butter, ice cream, soup, etc.) Even the body oil from washing your hands is considered a FOG.

These substances can enter your drain if you directly pour them down, but more likely, they’re entering your drain when you cook and clean dishes. During dishwashing, greasy residue gets swept up by the water and washed down the drain. As the residue cools, it hardens, just as grease does in a pan.

This hardened grease then clings to the sides of your pipes. More and more congealed FOGs add to this gunk layer over time, and other items (e.g., fruit peels, eggshells, hair, etc.) may also get stuck in the buildup. If left untreated, this FOG buildup can cause serious problems for your facility.

What Problems Do Fat, Oil, and Grease Cause in Commercial Drains?

When FOGs solidify in drains, they block part of the pipe, restricting water flow. There is only so much space in a pipe, so when FOGs take up part of that space, less water can flow through the pipe. This will initially cause slow drains, but if the blockage gets too bad or if something else gets caught in the buildup, you could be looking at clogs, backups, overflows, and more.

Additionally, all this organic matter sitting and rotting in your pipes doesn’t exactly smell great. This can lead to staff and visitor complaints, and it can also attract insects like flies (it can even become a habitat for pests like drain flies

For cast iron pipes, if this FOG buildup is left to sit, it can cause the pipes to rust. The more the pipes rust, the weaker they become. In a worst-case scenario, FOGs can actually rust a hole through cast iron pipes, necessitating costly pipe replacement.

Over time, FOGs can cause an array of issues for your facility, and these issues will become more costly and disruptive the longer they sit.

Regulations Against Fat, Oil, and Grease in Commercial Facilities

Controlling FOGs will directly benefit the functionality of your facility, but it’s also often required in many situations.

Due to the danger of FOGs not only for individual drainage systems but for municipalities’ sewer systems as a whole, the EPA requires that publicly owned sewage treatment plants have FOG control programs. Many of these programs require restaurants and other food service establishments to have a grease trap to reduce the number of FOGs entering the city sewage system—and most will also require that grease traps are pumped out at least once every three months.

As you can see, FOGs aren’t exactly something you want in your drains—neither for your facility’s operation nor the legal consequences of buildup. From here, the question becomes “how do you eliminate FOG buildup from drains?”

How to Prevent Fat, Oil, and Grease Buildup in Commercial Drains

Preventing FOG buildup in drains can be done in two ways: via manual removal or chemical maintenance.

Manual FOG removal can mean snaking a drain or skimming a grease trap or lift station. These methods effectively remove excess FOGs from the system before they can cause clogs, but they are more labor-intensive and require more frequent treatment than chemical options.

Meanwhile, chemical maintenance involves regularly dispensing a product into your drains to break down FOG buildup before it can form. These products can either be poured down by hand or released via an automated pump.

In either case, they effectively get to the root of the problem with less labor required, but they are usually more costly than manual removal methods—though they are a cost savings over time compared to more frequent pump-outs in lift stations or grease traps. It’s variable depending on your situation.

Either approach to FOG control can be effective, and beneath each umbrella, there are more varied options targeted toward your specific problem. Go the route that makes the most sense for you, and you can get your FOG problem under control and prevent damage from befalling your drains.

Learn About How State Chemical’s Grease-B-Gone® Can Control FOGs in Your Drains

If left unchecked, FOGs can cause some icky, disruptive issues. Now that you know how FOGs can impact your facility and the importance of treating them, watch the video below to learn how State Chemical’s Grease-B-Gone® can control FOGs in your drain.