How to Reduce Lift Station Pump-Outs with Chemical Maintenance

How to Reduce Lift Station Pump-Outs with Chemical Maintenance

Lift stations are a topic you probably never want to think about. Unfortunately, when your facility has one, you’ll have to think about it to some degree—especially when it smells and needs to be pumped out frequently. Overall, this can cause you a lot of headaches, but with chemical maintenance, it doesn’t have to be this way.

At State Chemical, we manufacture and distribute chemical solutions for various applications, including lift station maintenance. We know you don’t want to deal with constant lift station problems, but it can be difficult to find alternative options for a system whose sole purpose is to handle waste.

To help you learn how to reduce lift station pump-outs, we will explain the reasons behind frequent pump-outs, different ways to maintain your lift station, and the impact of maintenance on your facility as a whole. After reading, you’ll know what your facility needs to do to reduce lift station pump-outs.

Why Does My Lift Station Need Pumped So Frequently?

It’s normal for a lift station to need to be pumped out about once every six months. However, this requirement can be more or less frequent depending on the amount of fats, oils, and greases (FOGs) your facility handles.

FOGs are the reason behind most lift station problems, and they’re also the reason why lift stations need to be pumped out. When waste enters your lift station, it congeals—clinging to the sides of the system and hardening on the top. This can cause issues with float function, lift station performance, and odors.

Just think about it. If there’s a crusty layer of fat around your floats, the system won’t be able to accurately tell you when the water level is getting too high. If there’s sludge drifting through the whole wet well, the pumps may not be able to move out water properly. And if there’s a coagulation of mystery gunk hanging around your lift station, chances are it’s going to smell putrid.

This is why lift stations need to be pumped. If you notice any of these problems getting out of hand, it’s probably time to schedule a pump-out. Otherwise, you could face destructive equipment failure, overflow, or other costly problems.

But obviously, you want to avoid this as often as possible. Lift station pump-outs are disruptive and costly, and you have other priorities and expenses to attend to. Fortunately, while you can’t stop FOGs from entering your lift station, you can prevent them from coalescing and creating problems that necessitate pump-outs. This is where chemical maintenance comes into play.

Ways to Reduce Lift Station Pump-Outs

Reducing lift station pump-outs comes down to using chemical treatment or manual FOG removal options.

For example, some facilities prefer to skim their lift stations for 30–60 minutes per week. This means fishing out visible FOGs so they can’t congeal and create issues. And this can certainly help. It won’t be as effective as chemical maintenance, but it will remove FOGs and can reduce pump-outs.

This works better in facilities with low-to-medium FOG presence, as high-FOG lift stations would need an inefficiently high amount of skimming to significantly reduce pump-outs. Plus, if your maintenance staff is already short on time, this may not be favorable.

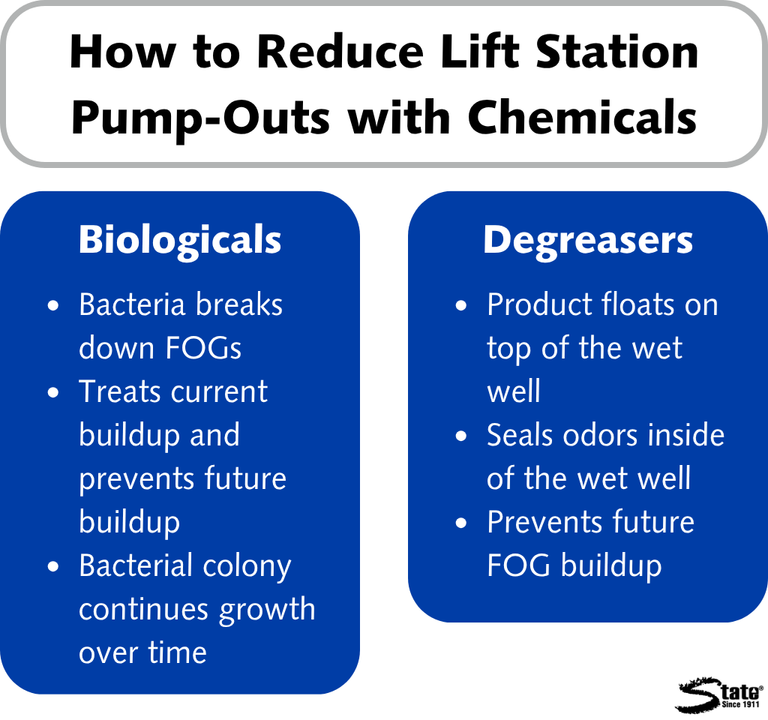

Meanwhile, chemical maintenance can reduce FOGs—and subsequently, pump-outs—in a more hands-off way. With chemical maintenance, you have two options for treatment: degreasers or biologicals.

In a lift station, degreasers act as a layer that floats atop your wet well. They seal foul odors inside the well, and they keep FOGs moving so they cannot form a crusty layer or become attached to the walls. If you already have severe buildup, degreasers alone probably won’t be enough to break it up, but they effectively eliminate odors and prevent future buildup from occurring.

On the other hand, biologicals actively work to break down FOGs currently in your lift station—making them both a reactive and a preventative measure to deal with buildup. They use bacteria to digest FOGs into water and air, helping waste to easily pass through the lift station with the rest of the water.

Because biologicals are bacterial, they build a colony in your lift station and will continue growing. This does mean that you have to maintain livable conditions for them to survive and continue growing (meaning that there must be a food source, temperatures of at least 40°F and no more than 120°F, and a pH of 6–9). You also must ensure the floats are set at levels that don't fully empty the well when the pump runs so that the colony can be maintained. But if you can sustain these conditions, biologicals work as an effective long-term solution, reducing FOGs and preventing future buildup so that your lift station needs fewer pump-outs.

Any of these options can work to reduce lift station pump-outs; what’s best for you depends on your specific issue and what solution you prefer.

The Impact of Chemical Lift Station Maintenance on Your Facility

Overall, when you use chemical maintenance for your lift station, your facility will smell better, have a lower risk of lift station malfunctions, and need fewer lift station pump-outs.

The main benefit of this is that it will save you money and time. Pump-outs often cost $500–$1,000, and they can take hours to complete. This is a significant disruption to your facility. With chemical maintenance, this can be reduced to every few years instead of every few months.

Similarly, your staff will notice the cleaner working conditions. No one wants to smell pungent waste seeping into their workplace all day. With reduced FOGs, your facility will smell better and seem cleaner—plus, you’ll know that your equipment is more reliable.

Lift stations can seem hopeless—after all, they’re a collection space for waste—but there are ways to keep them cleaner without costing you more money and time. Find the right chemical treatment for you, and your facility will be better for it.

Learn About State Chemical Biological Solutions for Lift Stations

Constant lift station pump-outs are disruptive and frustrating. Now that you know how to reduce lift station pump-outs through chemical maintenance, read this article to learn about State Chemical’s biological solutions for lift stations.