The Dangers of H₂S Gas Buildup in Wastewater Collections

The Dangers of H₂S Gas Buildup in Wastewater Collections

Confined wastewater spaces can contain hydrogen sulfide gas that can cause serious deterioration of your collection lines, as well as be lethal to your employees who may enter that space. This is the danger of hydrogen sulfide (H₂S) gas, which builds in sewers and related equipment. Left untreated, H₂S can lead to infrastructure damage or consequences as severe as nearly instant death.

At State Chemical, we manufacture and distribute various chemical solutions, including products to reduce H₂S. We know that the severity of H₂S can be intimidating, and you want to keep your wastewater collections system safe above all else.

To help you learn why H₂S is such a serious issue, we will explain what it is, what makes it dangerous, the regulations surrounding it, and how to reduce it in wastewater collections. After reading, you’ll know why you need to be careful about H₂S and how to proceed.

What is H₂S?

H₂S is a gas that forms due to the breakdown of organic waste. It's usually most recognizable by its signature smell of rotten eggs. When bacteria called biofilm digest organic waste, H₂S is produced as a byproduct. This means that in areas with high levels of organic waste, H₂S is likely to be present.

It can reach especially high levels in enclosed spaces. In these settings, there isn’t enough air to filter H₂S out, leaving it to continue building without any escape route. Usually, you wouldn’t need to worry about H₂S in an open area, such as outdoor areas of a wastewater treatment plant, because it’s more easily filtered out. However, in tighter spaces without proper airflow, such as lift stations, silos and pits, or sewers, there is a higher risk of H₂S exposure.

Why is H₂S Dangerous?

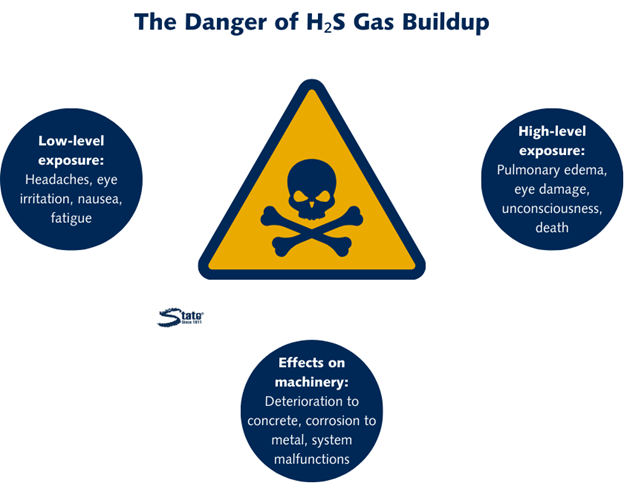

At the beginning of the article, we described how you could experience itchy eyes, throat irritation, coughing, and nausea within minutes of being exposed to H₂S. These are only a few of the dangerous effects that H₂S exposure can have on an individual.

When H₂S is at low levels, it can cause eye irritation, throat irritation, headaches, nausea, fatigue, loss of appetite, and dizziness. At higher levels, H₂S can cause all of these symptoms (usually at a greater severity) plus loss of smell, pulmonary edema, serious damage to the eyes, unconsciousness, and death—sometimes nearly instant.

These symptoms will differ based on the level and length of exposure, but even the more minor side effects are undesirable. Fortunately, most collections workers working in areas prone to H₂S gas wear monitors that sound when levels are too high, preventing these dangerous outcomes. Even still, H₂S can cause other issues.

H₂S can deteriorate concrete and corrode metal. This can create safety hazards, lead to system malfunctions, and necessitate more frequent equipment and infrastructure replacements.

Overall, H₂S can have severe consequences more quickly than you might imagine. This is why it’s important to make sure you’re taking proper precautions to keep your staff and guests safe.

H₂S Safety Standards

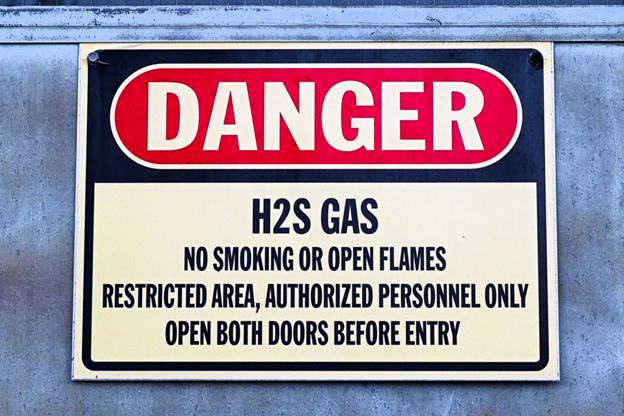

Protecting your wastewater collections system from H₂S means that you need to be prepared with safety information and follow standards as established by the Occupational Safety and Health Administration (OSHA).

These standards include providing proper ventilation in your H₂S-producing areas, wearing proper respiratory protection, having a permit for confined spaces, providing employees with safety information, knowing permissible exposure levels, and more. Depending on the specifics of your facility, there may be more regulations that apply to you.

More than anything, the best way to keep your facility safe is by keeping staff educated. Employees may not be as cautious if they’re simply told that they must wear protective gear in a lift station without the reason why. However, if they understand the possible health consequences of failing to do so, they may be more receptive and may better remember the importance.

Provide staff with training and educational materials, such as informative posters. Even small steps like this will keep your facility safer in the long run.

How to Reduce H₂S Levels

Even with safety regulations, you still want to keep H₂S to a minimum. Because H₂S is produced wherever there is organic waste, it’s impossible to eliminate it without eliminating the waste, which usually isn’t an option. However, there are ways to reduce H₂S in wastewater collections.

The most common treatment for H₂S is calcium nitrate. This is a product you can feed to H₂S-producing bacteria to satiate it, meaning it will stop producing H₂S. While not a long-term solution, this is a reactive measure that will effectively reduce H₂S in wastewater collections.

Additionally, you can use biological products. In this setup, the bacteria in the biological products would outcompete the H₂S-producing bacteria for the same food source. On this diet, they would grow a colony and eventually starve out the H₂S-producing bacteria, meaning there is less bacteria to even produce H₂S. This is a long-term solution that will keep H₂S in check even without consistent product usage.

With treatment to reduce H₂S, you can ensure that it’s kept at safe levels for your wastewater collections system.

Learn More About Reducing H₂S in Wastewater Collections

No one wants to be exposed to H₂S gas, but unfortunately, there are certain places where it’s always present, so you have to be cautious about it. Now that you understand the dangers of H₂S gas, read this article to learn more about how to reduce it using biological and chemical solutions.