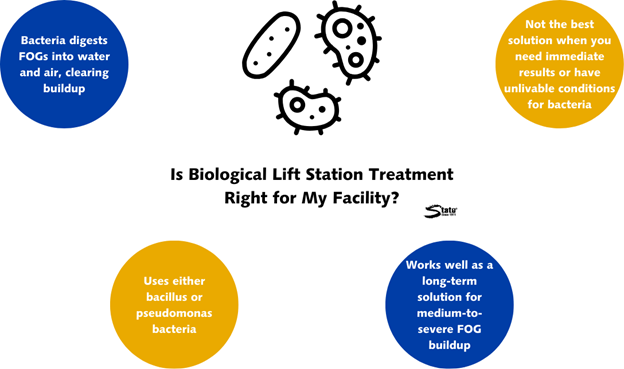

Is Bacterial Treatment Right for My Lift Station?

Is Bacterial Treatment Right for My Lift Station?

Gunky, slimy, fatty lift station wet wells are about as unappealing as it gets. You don’t want to deal with a nasty pit—and you especially don’t want to pump it out constantly. But will biological products be the solution to your lift station woes, or should you explore alternative options?

At State Chemical, we manufacture and distribute chemical solutions for a variety of purposes, including biological lift station treatment. We know that it can be frustrating to deal with constant lift station problems, especially because it can sometimes feel like there isn’t a solution at all.

To help you determine the best treatment method for your lift station, we will explain biological lift station treatment, how it works, when it should be used, and alternative options. After reading, you’ll know whether biological products will be effective in your lift station or if you should seek other treatment options.

What is Bacterial Lift Station Treatment?

Bacterial or biological lift station treatment involves using bacteria to digest fats, oils, and greases (FOGs) and convert them into water and air as byproducts. This allows the digested FOGs to pass easily through the lift station with the rest of the water.

Through this method, a colony of bacteria will form in your lift station. As long as conditions remain livable, they will continue multiplying, reducing FOG buildup along with the resulting pump-outs and odors. For bacteria, livable conditions mean that there must be a pH of 5–9, temperatures of at least 40° F and no more than 120° F, oxygen when applicable, and a food source (meaning FOGs). If your lift station fits these criteria, biologicals are an option for you.

How Does Biological Lift Station Treatment Work?

As previously mentioned, biological lift station treatment works via bacterial digestion of FOGs. This process looks different depending on the type of bacteria, however. In biological lift station maintainers, two main types of bacteria may be used: bacillus and pseudomonas.

Bacillus bacteria are spore-based bacteria. This means they live in a spore (a kind of cocoon, if you will) until conditions are appropriate for them to come out of the spore. Once there’s a food source, they emerge from the spore and start working to control FOGs in your lift station.

A benefit of bacillus bacteria is that they can return to their spores if conditions become unlivable, emerging again once conditions improve. This also means they are less susceptible to damage during shipping or other extreme conditions.

Once they enter your lift station, bacillus bacteria take two to three hours to initially activate and are fully activated after 24 hours. From there, they continue multiplying as long as conditions remain stable.

Meanwhile, pseudomonas bacteria are live, non-spore-based bacteria. Before they even enter your lift station, they are active—immediately working to reduce FOGs in the wet well. This quick-working action is a benefit, but it also means these bacteria are more sensitive to their environment.

So, if your lift station cannot support livable conditions, your pseudomonas bacteria will die off and the FOG buildup will continue unchecked. Additionally, the bacteria could die off even in shipping if the truck gets too hot, for example.

But if your lift station does have the conditions to support them, pseudomonas can be more effective than bacillus—mainly because they start working faster. It’s just about choosing the right option knowing your facility.

Additionally, for both types of bacteria, there is a way to speed up FOG breakdown and increase effectiveness: aeration. Aeration involves using a device to increase the oxygen flow throughout the lift station. With extra oxygen throughout the lift station, bacterial reproduction rates increase—and more bacteria means more FOG consumption. Aeration can also benefit a lift station by maintaining movement on the surface, which can limit the chances of a grease cap forming.

When Should You Use Bacterial Lift Station Treatment?

Biological products should be used to treat lift stations as a long-term solution. If you have moderate-to-severe FOG problems and have the time to wait for bacteria to activate, biological lift station treatment is the solution for you.

However, maybe you need immediate results. Maybe your lift station can’t support livable conditions for bacteria. Maybe you need the strongest possible option.

In these cases, you’ll need to use an emulsifying product to control FOGs in your lift station.

Alternative Methods of Controlling FOGs in Lift Stations

Emulsifiers are the main alternative to biologicals for FOG control in lift stations. Where biologicals digest FOG buildup, emulsifiers liquefy FOG buildup so it can easily pass through the lift station and sewer lines with the water.

Emulsifying products can be ideal because they work so quickly. If your lift station buildup is severe, this can get the problem under control much more quickly while also acting as a long-term solution with continued use.

However, there can be issues with emulsifiers too. While they work quickly, they get diluted as they travel through the sewer system, allowing potential FOG reformation further down the sewer line. Because of this, emulsifiers are heavily regulated in many municipalities, so you’ll need to check your local laws to determine whether you’re allowed to use them in your lift station.

Meanwhile, to simply control FOG buildup and cap off odors, you can use a floating degreaser. This ensures that FOGs can’t form a grease cap over your lift station and affect your floats—plus, it replaces foul odors with a more pleasant scent.

However, floating degreasers cannot fully eliminate the FOG buildup that’s already present; they only come into contact with the grease that is at the top of the water level. If you’re looking to deal with already-present FOGs, floating degreasers are not your solution.

If chemical maintenance doesn’t seem ideal, you can also complete manual maintenance to control FOGs in your lift station. The most common way to do this is through skimming, where you’ll use a tool to break up and remove FOGs from the wet well.

Skimming is an effective maintenance method, especially for less severe FOG buildup, but it is time-consuming and tedious where chemical maintenance is hands-off. If you’re willing to dedicate the time and energy to skimming, your lift station will see the benefits, but it’s important to understand the importance of maintaining a consistent schedule beforehand.

Lastly, you can also choose not to control FOGs in your lift station. This will mean that you need to pump out your lift station more frequently and deal with odors, but if you’d rather not complete maintenance, this is also an option.

Learn About State Chemical Biological Lift Station Treatment Options

You don’t want to deal with the consequences of a gunky lift station, but it can be hard to know what to use for maintenance. Now that you know how biological products can help control FOGs in your lift station, watch the video below to learn about how State Chemical’s product Line Bac’r can work in your lift station.