How to Prevent Grease Trap Overflows

How to Prevent Grease Trap Overflows

Picture this: you’re the manager of an independent restaurant. After a long shift, you go home for the evening—only to get a flurry of phone calls right before closing. You rush over to find that the grease trap overflowed, there’s brown water flooding the kitchen, and it’s up to you to fix it.

It’s safe to say that this is not how you wanted to spend your evening. Unfortunately, this is the type of disruption facilities deal with when they face frequent grease trap overflows.

At State Chemical, we manufacture and distribute chemical and biological solutions for various applications, including grease trap maintenance. Reactively treating these problems creates more hassle over time, but how can you prevent grease trap overflows altogether?

To help you best maintain your grease trap, we will cover why grease traps overflow, the consequences of frequent overflows, and ways to prevent grease trap overflows. After reading, you’ll understand what causes this and how to avoid backups moving forward.

Why Does My Grease Trap Keep Overflowing?

If your grease trap repeatedly overflows, you’re likely dealing with an excess of fat, oil, and grease (FOG) buildup.

Of course, the entire purpose of a grease trap is to catch FOGs and prevent them from escaping into the drain line. But there are only so many FOGs that a grease trap can handle at once. Once a grease trap is one-quarter full, it needs to be pumped out.

If pump-outs are skipped or if too many FOGs are building between pump-outs, overflows can happen. Maybe you used to be able to wait three months between pump-outs, but now, your grease trap gets a quarter of the way full after six weeks. When these changes go unnoticed, grease traps are more likely to overflow.

This is often because the grease trap itself gets backed up, but this can also happen when overflowing FOGs slip out of the grease trap into the pipes. From there, a clog could occur, stopping flow from the grease trap to the pipes and causing overflows.

Overflows can also sometimes happen when a foreign object blocks the water flow, but most often, FOGs are the culprit at hand.

What are the Consequences of Frequent Grease Trap Overflows?

Frequent grease trap overflows can lead to many different consequences—some obvious, some less immediately evident.

Facility Damage

The most pressing consequence will be damage to your facility. Overflows can damage floors, baseboards, nearby equipment, and more. Just as a flood causes water damage, an overflow causes similar issues for unfortunate facilities.

Downtime for Your Business

While the overflow is active and the grease trap is down, this will also lead to downtime for your business. And with downtime, there is lost revenue, wasted labor time, and customer frustration.

Emergency Maintenance

When your grease trap is actively overflowing, you’ll need to call a professional as soon as possible to fix the problem—until that happens, your facility will be stuck trying to prevent further damage.

Unfortunately, emergency maintenance can be costly, and it’s considerably more disruptive than the preventative maintenance that would have stopped this issue from occurring in the first place. When this is required frequently, it can be a significant financial burden to your facility.

Reduced Grease Trap Lifespan

Additionally, when a grease trap is not maintained, the system takes on damage more quickly than a well-maintained grease trap. This results in the grease trap having a shorter lifespan and needing to be replaced years sooner than it would if it were well-maintained.

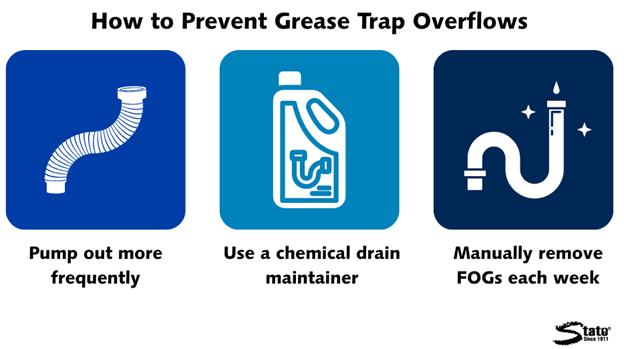

How to Prevent Grease Trap Overflows

With preemptive intervention, grease trap overflows can be avoided. There are several different ways to do this.

Pump Out the Grease Trap More Frequently

No matter your situation, you should be pumping out your grease trap at least once every three months—most municipalities even legally mandate this. However, if your grease trap is getting one-quarter full more frequently than this, you should also be pumping out more frequently.

Pumping out your grease trap removes the FOGs that could otherwise cause overflows. By keeping up with it consistently, you’re more likely to catch anything problematic.

However, as you know, pump-outs are disruptive and costly. For this reason, you may prefer another method instead of more frequent pump-outs.

Manually Remove FOGs

Another way to prevent grease trap overflows in addition to regular pump-outs is by manually removing FOGs. This often involves skimming the grease trap with a specialized tool to extract FOGs by hand.

While effective, this task can be tedious, as it must be done at least once per week to make a significant difference in FOG buildup. After a while, this can take a good chunk of your staff’s labor time.

Regularly Use a Commercial Drain Maintainer

To best maintain your grease trap and prevent overflows, you should regularly use a commercial drain maintainer.

In this method, you would regularly apply a drain-maintaining product to your grease trap either by hand or via an automated dispenser. From there, the product would liquefy (emulsify) or digest (biological) FOG buildup so it can pass easily through the pipes with the water.

This way, FOGs are kept under control routinely, prolonging pump-outs while also preventing overflows. When on an automated pump, this can be done without any interruption or extra work for your staff.

Learn How State Chemical’s Line Bac’R™ Can Maintain Your Grease Trap

Frequent grease trap overflows are disruptive, damaging, and costly. Now that you know how to prevent overflows, watch this video to learn how State Chemical’s Line Bac’R™ can help you maintain your grease trap.