Cost of H₂S Removal vs. Cost of H₂S Damage

Cost of H₂S Removal vs. Cost of H₂S Damage

Pipe deterioration, equipment degradation, injuries, and more can be caused by hydrogen sulfide (H₂S) buildup in wastewater collections lines. If you’re reading this article, you probably know that. But you may still be wondering: is the cost of H₂S treatment worth it, or would it be more cost-effective to complete repairs as needed?

At State Chemical, we manufacture and distribute chemical solutions for various applications, including H₂S wastewater treatment. When it comes to an investment like H₂S treatment, you want an effective solution, but you also want to ensure you’re spending wisely.

To help you determine whether H₂S treatment is worth it, we will explain forms of H₂S treatment, the cost of not treating H₂S, and the cost of treating H₂S. After reading, you’ll know whether H₂S treatment is worth the expense for your facility.

How to Remove H₂S from Wastewater

First, it’s important to establish what removing H₂S from wastewater involves. Usually, you will use one of two treatment methods: chemical or biological.

Chemical treatment involves using a chemical product to reduce H₂S gas. The most common chemical solution is calcium nitrate, which feeds the biofilm that produces H₂S, keeping it satiated to prevent further production. Another popular chemical treatment is to use a scavenger, which burns through the biofilm to reduce H₂S.

Meanwhile, biological treatment involves using bacteria to reduce H₂S gas. Bacteria are fed into your system, and from there, they grow a colony. This colony continues multiplying, outcompeting the sulfate-reducing bacteria (SRB) that produce H₂S. Outcompeted, the SRB will starve and die off.

Depending on your facility’s preferences, any of these solutions can be effective. The main drawbacks are that calcium nitrate requires additional equipment and a large amount of product, scavengers can be harsh on equipment and cause chemical burns, and bacterial products usually come at a higher upfront cost. If you'd like to learn more about which type of H₂S treatment might be a fit for your needs, read this article.

Products may differ by brand, but these are the main forms of H₂S control on the market.

How Much Does H₂S Damage Cost?

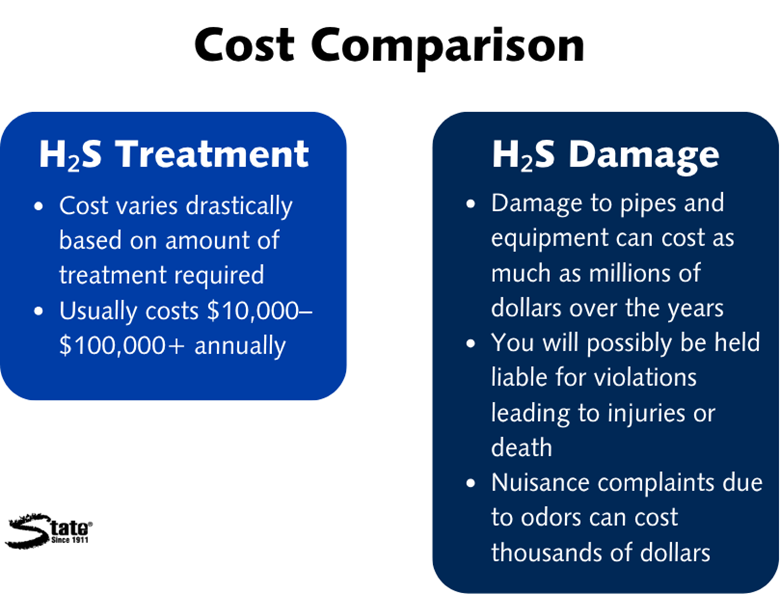

When left untreated or without a sufficient volume of treatment, H₂S can wreak havoc on a facility and throughout collection lines.

You might first recognize H₂S through a strong odor of rotten eggs. The odor itself won’t do any harm, but if widespread enough, it can lead to the community filing nuisance complaints—and their associated fines can be costly. Exact numbers vary by municipality and odor severity, but it’s not uncommon for these fines to be thousands of dollars if not higher.

But H₂S won’t just cause foul smells—over time, it will also cause physical damage to your infrastructure. This can mean corroded metal (e.g., pipes) and deteriorated concrete among other damages to associated equipment.

According to the Environmental Protection Agency (EPA), this can necessitate the replacement of entire sewer systems in as little as 10–20 years when they are designed to last 50–100 years. Similarly, it has been known to cause electrical and mechanical equipment with a usual lifespan of 20 years to break down in as few as five years.

These kinds of sewer replacements can cost millions of dollars while the costs of other equipment can be tens of thousands of dollars. With these kinds of replacements required every 5–20 years, you could be spending roughly $100,000 each year just to keep your system up and running.

And when considering these costs, it’s also important to consider the toll of workplace injuries. H₂S causes damage to metals and concrete, so it makes sense that it can also cause considerable damage to the human body.

Low-level exposure to H₂S can lead to eye irritation, throat irritation, headaches, nausea, fatigue, loss of appetite, and dizziness. This is already unpleasant, but at higher levels, H₂S can cause all of these symptoms (usually at a greater severity) plus loss of smell, pulmonary edema, serious damage to the eyes, unconsciousness, and death—sometimes nearly instant.

If your workplace is found not to comply with OSHA's H₂S safety standards, you could face costly fines. Further, if these violations cause employee injuries or even deaths, you could be held liable.

All of this considered, over the years, foregoing H₂S treatment can potentially cost you millions of dollars—not to mention the cost of your staff’s safety. But that leaves the question: how does H₂S treatment compare?

How Much Does H₂S Removal Cost?

Depending on which specific company and product you use to reduce H₂S in your wastewater collections system, the cost of your H₂S treatment can vary drastically. Additionally, depending on the severity of your H₂S buildup and the size of your facility, the cost can also fluctuate substantially.

Most companies do not publicly disclose the prices of their H₂S treatment products, and it would be unethical for us to share these prices on our own website. Instead, we will use State Chemical’s cost for an H₂S treatment program as a reference point.

With State Chemical, you will pay $10,000–$100,000+ annually for H₂S treatment. Again, this cost varies drastically depending on the amount of treatment required.

As you can see, in most cases, this will be equivalent to or less than the potentially hundreds of thousands of dollars you’d pay each year to repair/replace sewer equipment without treatment. Plus, this method is less disruptive than repairs and safer for staff in the long run.

Learn About State Chemical Wastewater Agreements

Treating H₂S is the best way to prevent future equipment breakdown and protect staff safety, but it can be worrisome to consider the cost of such an investment. Now that you know how much H₂S treatment costs compared to the cost of foregoing treatment, watch this video to learn more about how State's wastewater program agreements work.